Downloads : technical modifications reserved

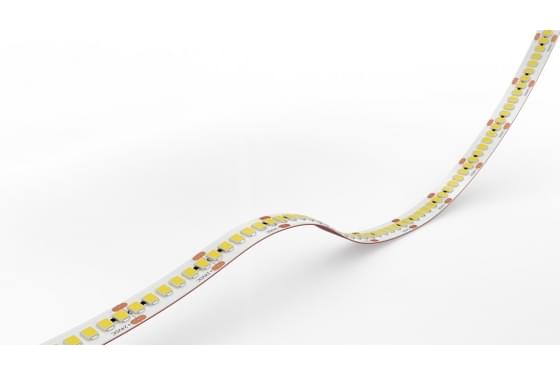

LED Flex Lumen Line 240

Flexible LED strip lights are used all over the world in various industrial, commercial and residential projects. LED strip lighting is popular among many Architects and Lighting Designers due to the improvements in efficiency, color options and brightness.

Cutting LED strips is very simple thanks to the cut lines along the strips. At each cut point there is a black line with copper solder pads that sit on each side. The copper solder pads make it so each strip piece is addressable even after being cut. This makes it possible to connect LED strips together or connect the strip in a different area of your home.

The LED strips have a 3M adhesive backing for simple mounting options. The low profile, flexible strip has a peel-off backing which exposes the 3M adhesive, making for a simple peel-and-stick install.

The new range offers greater variations in cutting intervals, promising greater customization and bespoke outcomes.

Production specification:

- Dimension: L5000/W10mm

- PCB increment: Power connection and cut point every 25mm

- LED pitch: 4.17mm

- Beam angle: 120°

| CRI | Power consumption | Luminous flux lm/m | Luminaire efficacy lm/w | ||

| 240 - 2100K | 97.4 | 24.02W | 1347 | 56.08 | |

| 240 - 2300K | 97.6 | 23.63W | 1403 | 59.37 | |

| 240 - 2700K | 96.5 | 23.28W | 1716.3 | 73.72 | |

| 240 - 3000K | 95.1 | 23.7W | 1724.9 | 72.78 | |

| 240 - 4000K | 92.5 | 23.82W | 1865.2 | 78.3 | |

| 240 - 6000K | 87.2 | 23.81W | 1845.5L | 77.51 |

See specification for more information here